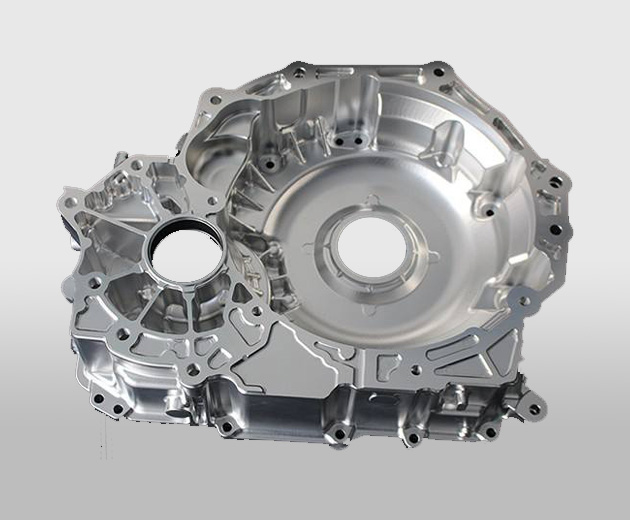

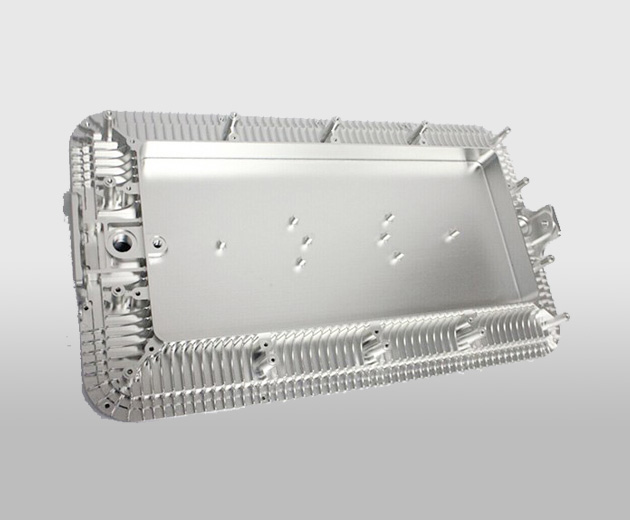

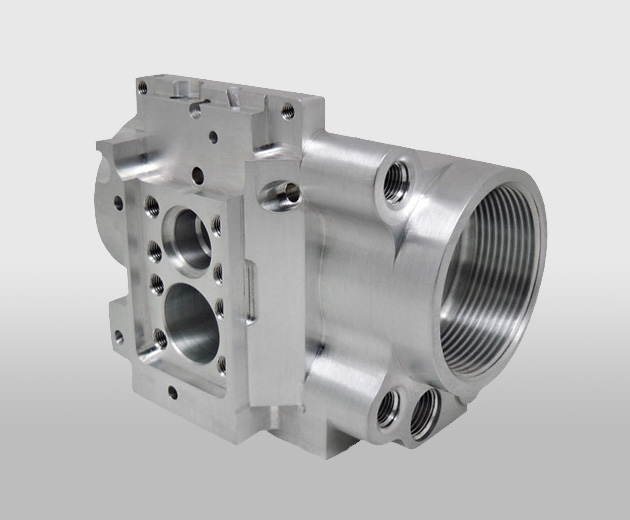

From Prototypes to full production runs,Winners Rapid is a highly responsive, ISO-certified CNC machining supplier. We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes.We make the parts from the drawings fully in our factory via various capabilities include CNC center, CNC turning, milling, grinding, drilling, tapping, EDM , wire cutting and deburring etc.Start your CNC Milling project today and let Winners Rapid manage the entire process for you.

62 x 30 x 16

Part size limitations |

Metric units |

Imperial units |

Aluminum, Copper, Brass, and Plastics |

2000x1500x200mm |

78.7×59.0x7.8 in |

Stainless Steel, Tool Steel, Alloy Steel & Mild Steel |

1500x800x400mm |

62×30×16 in |

Minimum feature size |

Ø 0.50 mm |

Ø 0.019 in |

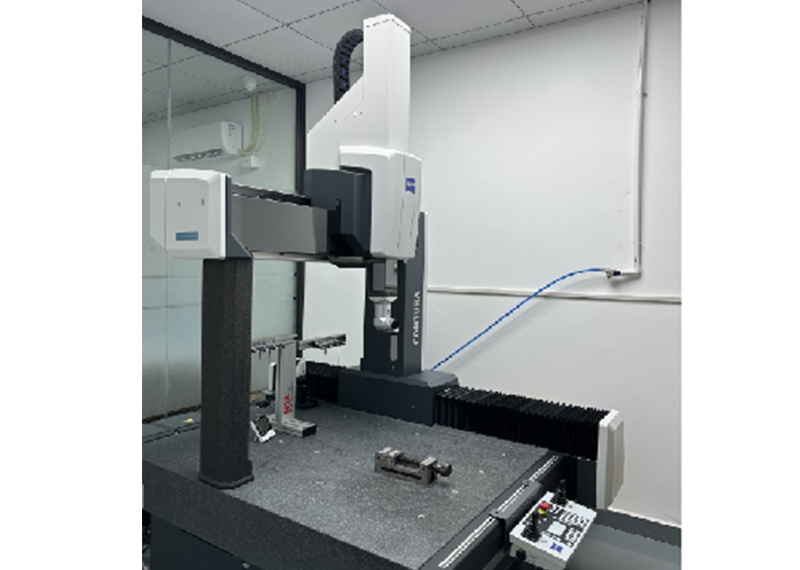

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts. Material Certification Full Dimensional Report Advanced Inspection Equipment

A major advantage in using CNC milling as a prototyping or production technique is the huge range of materials that are available.Winners Rapid are experienced in machining a wide variety of materials including both metals and plastics,while the choice of material depends on the part design and intended application.Please see the list for a sample of the materials we work with. If you desire a material not in this list,please contact Winners Rapid directly if there is a specific material that you require.

Aluminium |

AL6061-T6/T651/T6511, AL6063, AL6082, AL7075,T651, AL5083, AL2024,AL5052-H32, |

Stainless Steel |

SS303, SS304/304L , SS306, SS316, 410, 416,420F,430F,440C,630, 17-4 PH, PH 13-8 Mo |

Titanium |

Titanium Ti-6Al-4V (TC4), Titanium TA2 ,,GR5 ect |

Steel Alloy |

#45 Steel, 1018 Steel, 4043 Steel, 4130 Steel, 4140 Steel, 8620 Steel |

Other Material |

Brass 360, Lithium Bronze,Beryllium Bronze,Copper C101,Magnesium AZ31,A2 Tool Steel, D2 Tool Steel, Inconel 625, 718,Tungsten, Zinc |

Plastic Material |

ABS,PC+ABS,PC,POM,PP,PEEK,HDPE,PETF,PMMA,PVC,NYLON/NYLON+30%GF,PPS,PEI,PBT,PTFE,UHMW ect. |

If you need custom milling, one-of-a-kind prototypes, other precision CNC milled parts, or complete turnkey service, look no further than Winners Rapid. Our on-demand manufacturing can deliver high-quality metal or plastic milled parts for rapid prototyping or low-to-high volume production runs.Request a quote today—most quotes are returned within fews hours.