You need metal and plastic parts,but you do not need millions...at least not right away. So how do you justify spending tens of thousands of dollars on tooling that will only be used to manufacture a limited quantity of parts? You're in luck! The Winners Rapid has a solution for you. Low-Volume Manufacturing is an ideal solution for managing your inventory and testing the market before producing larger quantities.To keep up with demand, production lines turn to low-volume manufacturing. Through our low-volume manufacturing service, we can provide you with hundreds of thousands of parts so that you can get products to market in weeks instead of months.

Many of our clients need more than just machined parts, which is why we also offer 3D printing and plastic injection molding and other services that meet equally stringent quality standards and compressed turnaround times, making a full suite of rapid manufacturing technologies that provide advantages for prototyping and production available to our customers. To experience the rapid response and radical quality that drives our CNC machining and low-volume manufacturing solutions, upload a 3-D model file and request A Free Quote today.Learn more about our low-volume production capabilities:

There is no minimum quantity requirement,we provide customer-oriented manufacturing solutions for different type of projects.

Quotes within hours,parts within days,our quick turnaround times ensure that you’ll get your prototypes to help you accelerate speed products to market.

We have built up an efficient rapid manufacturing system which allows us to offer competitive prices that can match any offer.

The tightest tolerance +/-0.001" to +/-0.0002" (+/-0.025mm to +/-0.005mm), we are able to make precise parts with tight tolerances for aerospace and medical industries.

We supply a wide array of commercial-grade plastics ,metals and elastomers materials suitable for Rapid Prototypes and On-demands Part Manufacturing.

We have a team of professional engineers, machinists and skilled craftsman with more than 10 years of experience, which allows us to completely grasp your exact project requirements from prototype to production.

We provide free,professional and quick-turn manufacturing feasibility analysis for Rapid Prototypes and On-demand Production Parts.

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts.

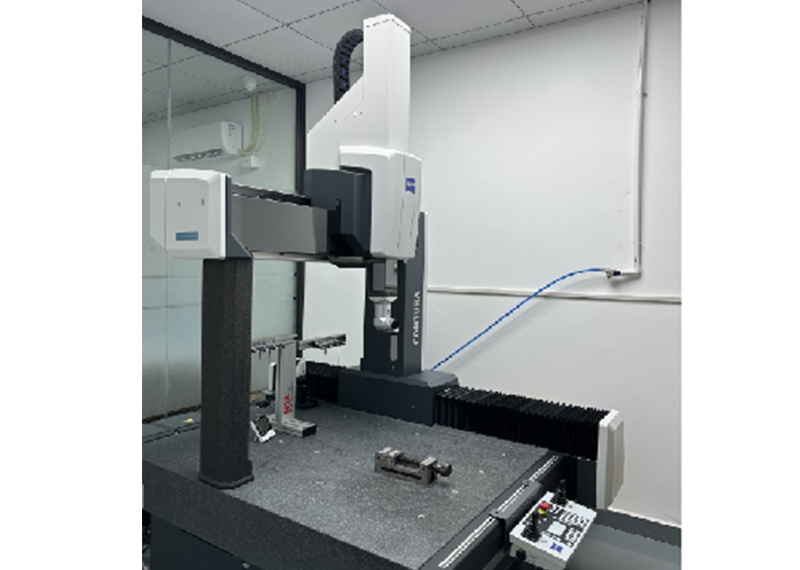

Material Certification, Full Dimensional Report, Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges. With high-precision industrial manufacturing, a variety of available finishes on solid metal or plastic parts, and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.