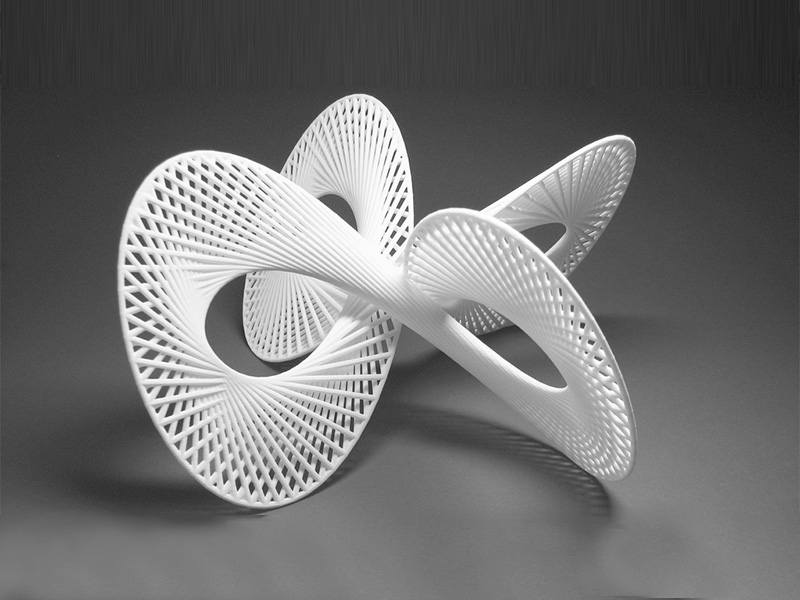

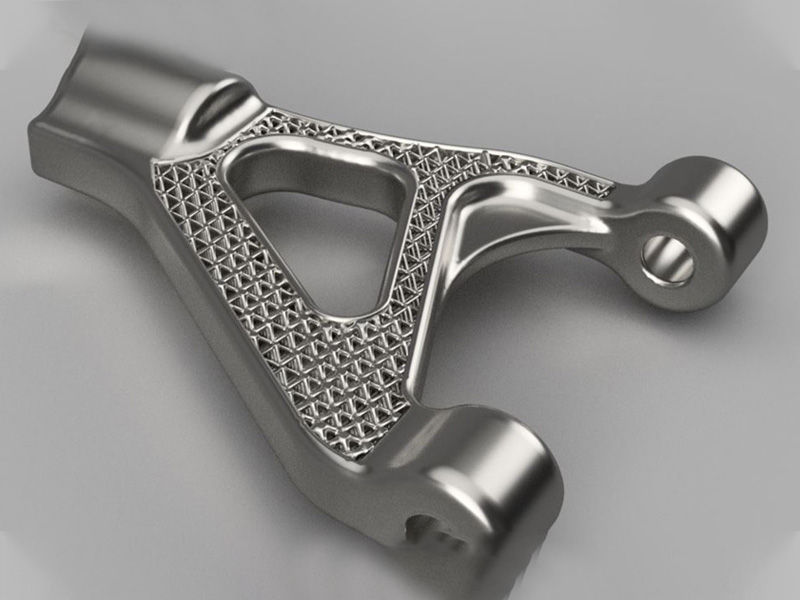

3D printing is a manufacturing process in which material is laid down, layer by layer, to form a three-dimensional object.Additive technologies enable the ability to fabricate geometries that were previously not manufacturable.More and more used today to make proofs of concept, prototypes or end-products. Our good partners produce exceptional parts at competitive prices. Simply tell us what you need then trust Winners Rapid to manage the whole process for you.With state-of-the-art machinery capable of producing both metal and plastic parts, Winners Rapid is your additive manufacturing partner.

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts. Material Certification , Full Dimensional Report , Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges. With high-precision industrial manufacturing, a variety of available finishes on solid metal or plastic parts, and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.

Whether your project requires sintering, melting, stereolithography, low or high volumes, we are ready to help. Winners Rapid ’s expertise, excellent quality, quick lead time will provide you with the best customer experience.

Now do you know which 3D printing technology to choose? Share your choice with us. If your 3D file is ready to be printed, you can upload it to us to get an instant quote, and receive your part printed in a few days.