Winners Rapid offers the latest CNC services for both, pre-series and large series production. Our CNC controlled equipment features 3, 4, 5 axis CNC machines with three and four jaw chuck work holding, EDM, live tooling, pallets, and in-house fixturing and tooling. Our machine shop produces high complexity parts that might seem impossible to the average job shop. The technology and equipment we use enable our machining staff to focus on smart planning, improving workflows and discovering innovations. We are always improving our capabilities to making close tolerance, unique parts an everyday occurrence. You can count on Winners Rapid to deliver the most critical and complex CNC machining products on time and with the highest quality.

To learn more about our CNC production machining services, contact us today. If you’re looking for a partner for your next machining project,

request a free quote from our experts now.

Size |

Metric units |

Imperial units |

Max. part size for metal and plastic materials |

650 x 650 x 300 mm |

25.5 x 25.5 x 11.8 in |

Min. feature size |

Ø 0.50 mm |

Ø 0.019 in |

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts.

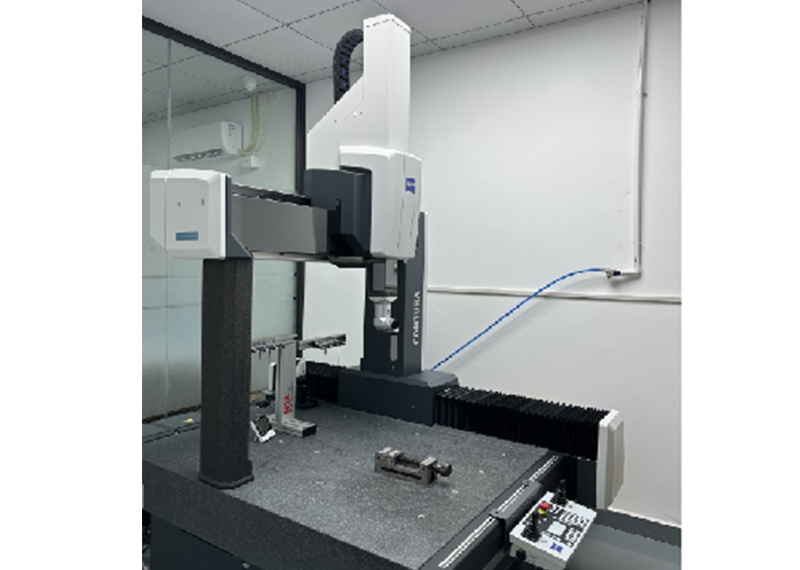

Material Certification , Full Dimensional Report , Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges.

With high-precision industrial manufacturing, a variety of available finishes on solid metal or plastic parts, and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.

A major advantage in using CNC machining as a prototyping or production technique is the huge range of materials that are available.Winners Rapid are experienced in machining a wide variety of materials including both metals and plastics,while the choice of material depends on the part design and intended application.Please see the list for a sample of the materials we work with. If you desire a material not in this list,please contact Winners Rapid directly if there is a specific material that you require.

Aluminium |

AL6061-T6/T651/T6511, AL6063, AL6082, AL7075,T651, AL5083, AL2024,AL5052-H32, |

Stainless Steel |

SS303, SS304/304L , SS306, SS316, 410, 416,420F,430F,440C,630, 17-4 PH, PH 13-8 Mo |

Titanium |

Titanium Ti-6Al-4V (TC4), Titanium TA2 ,,GR5 ect |

Steel Alloy |

#45 Steel, 1018 Steel, 4043 Steel, 4130 Steel, 4140 Steel, 8620 Steel |

Other Material |

Brass 360, Lithium Bronze,Beryllium Bronze,Copper C101,Magnesium AZ31,A2 Tool Steel, D2 Tool Steel, Inconel 625, 718,Tungsten, Zinc |

Plastic Material |

ABS,PC+ABS,PC,POM,PP,PEEK,HDPE,PETF,PMMA,PVC,NYLON/NYLON+30%GF,PPS,PEI,PBT,PTFE,UHMW ect. |

CNC machining is ideal for projects requiring production-grade materials and rapid prototyping of tight tolerance plastic and metal parts with excellent surface finishes. Tolerances are greatly affected by part geometry and type of material.

We specify a standard dimensional tolerance of ± 0.005" for CNC machined parts. However, we have much capability to achieve a tighter tolerances on our routers, lathes, 3-axis mills and 5-axis mills. If you require a tighter tolerance, please contact us, as tighter tolerances may increase the cost of your project and have to be clearly defined upon on the 2D drawings of ordering.

ISO 2768 is a standard for general tolerances, specifically covering linear dimensions, angular dimensions and geometrical tolerances.The ISO 2768 standard comes in two parts, namely ISO 2768-1 and ISO 2768-2.

✔ As Machined (Ra 3.2μm, 126μin), Smooth Machining (Ra1.6µm, 63 µin)

✔ Brushed (1.2 Ra μm/47 Ra μin), Engraving, Silk Screening, Painting

✔ Bead Blasted, Powder Coating Polishing (0.8 Ra μm/32 Ra μin)

✔ Black Oxide Heat Treating Chromate Conversion Coating (Alodine)

✔ Bead Blasted + Anodized Type II (Matte), Anodized Type III (Hardcoat)

✔ Brushed + Anodized Type II (Glossy) , Brushed + Electropolished (Ra0.8µm, 32µin)

We have built a storied reputation for providing the fastest turnarounds for all of your machining needs.

For consistently high-quality,rapid results,Winners Rapid is always ready to deliver.Now we are ready to tackle your project.