Winners Rapid custom sheet metal services offer a cost-effective and on-demand solution for your manufacturing needs. From one off prototypes to low-volume production, we offer a variety of manufacturing methods, material properties, and finishing options. Our partner factories have vast capacity and use state-of-the-art equipment to manufacture your bespoke parts. By fully-automated CNC laser cutting, CNC punching, CNC panel bending & laser welding along with conventional fabricating processes.Our sheet metal services offer a fast and cost-effective solution for sourcing durable, prototype or end-use metal parts that meet the specifications for industries such as aerospace, lighting, automotive, food beverage, electronic, hardware and medical industries.

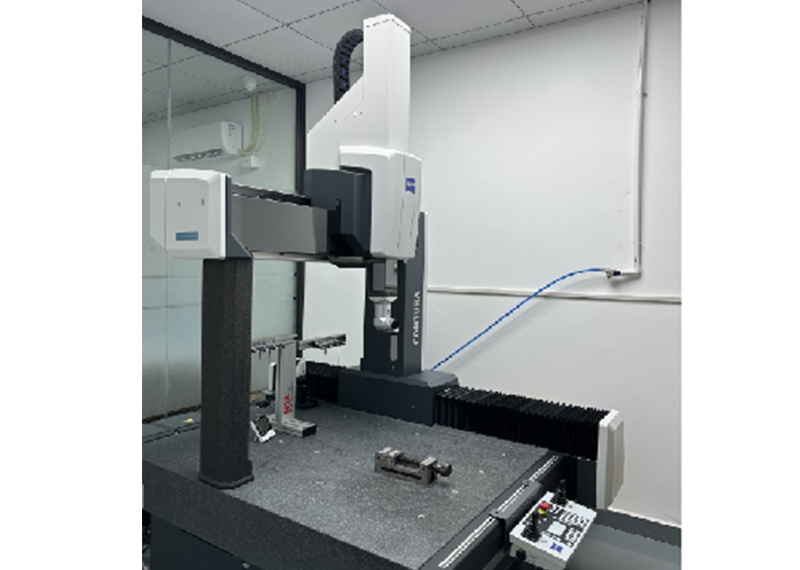

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts. Material Certification , Full Dimensional Report , Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges.

With high-precision industrial manufacturing, a variety of available finishes and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.

Sheet metal fabrication isn’t just about cutting and bending. In cases where multiple metal parts need to be joined, welding and riveting become important operations.

When dealing with tight tolerances and thin wall products, the heat produced by welding has a direct effect on metal quality.As a rule, heat should be minimized whenever possible.

Rivets are used to fasten two or more pieces of metal together and can be purchased in steel, stainless steel, and aluminum. The advantages of riveting over welding include their ability to fasten dissimilar materials together or their ability to fasten areas that are not accessible to other processes.

At Winners Rapid, we want to be your one-stop-shop for sheet metal fabrication and provide complete, turnkey parts, components, and assemblies. We provide inclusive, comprehensive solutions, including sheet metal fabrication, precision metal stamping, and sheet metal prototyping and engineering services.

Request a quote on your precision fabrication project on tight deadlines, or contact us to find out what we can do for you.

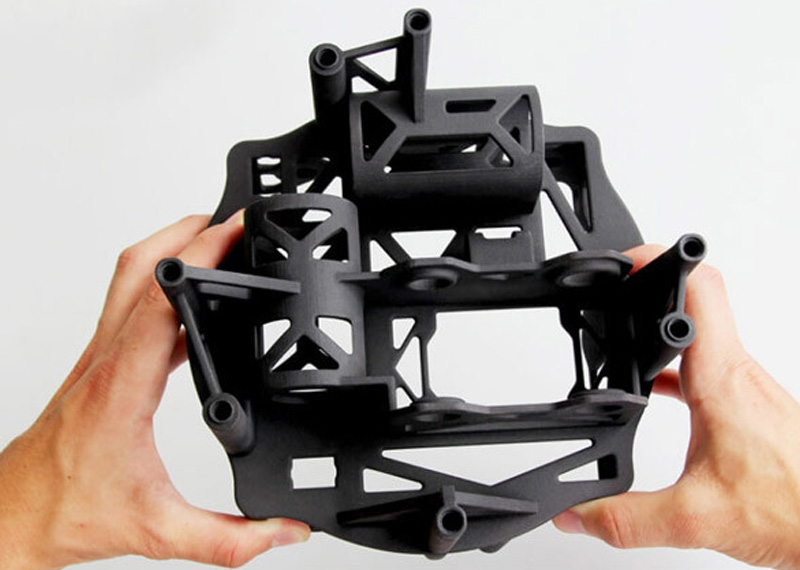

FDM,SLA,SLS,MJF,

Polyjet,DMLS

Production quality parts

withoutthe tooling investment.

T1 samples as fast as 10 days

withlow minimum order quantities.

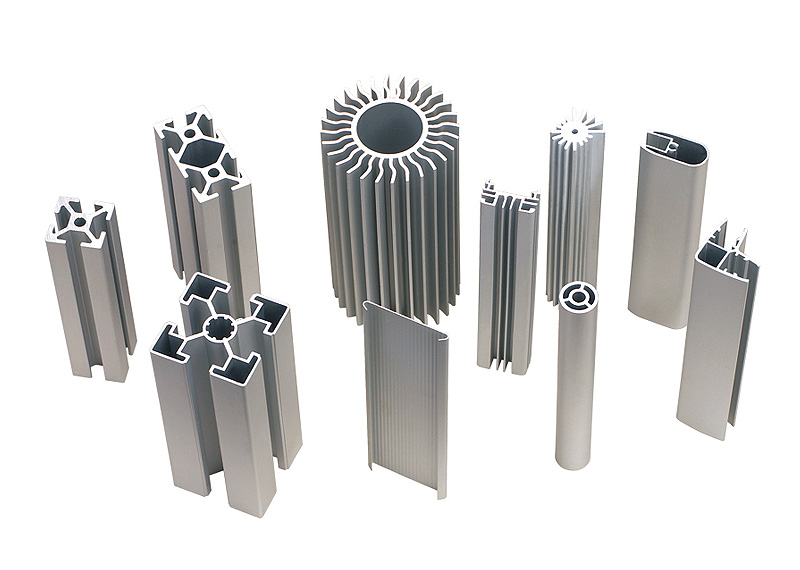

Custom prototypes extrusions in as little as 3 weeks,cut to your specified sizes are available.