On-Demand Aluminum Extrusion Production

No Minimum Order / Global Delivery / ISO 9001:2015 Prototype To Production , Quick Turnaround , High Quality

Get QuoteCustom Aluminium Extrusion

Aluminum extrusions are aluminum shapes and products that have been created through the extrusion process.Winners Rapid have no Minimum Order Quantity (MOQ) for the amount of extrusion needed. Whether you need a mass production or simply a one-off custom extrusion, Winners Rapid’s solid partner has the capability and flexibility to deliver for your project.Using the latest extrusion techniques, our rapid aluminum extrusions process offers Prototype Extrusions in a little as 3 weeks. Trust Winners Rapid to manage your project and deliver your parts on-time, to specification and at a competitive price.

1000+ Aluminum Extrusion Parts Delivered To Global Leading Companies

Winners Rapid supply industries and OEMs across the board,from medical to construction to furniture to hardware. For channels, hollows, and solid profiles, a wide variety of press sizes and tonnages are available to push your profile in a cost effective manner.If you need rapid prototyping or low-volume manufactured products with a definitive cross-sectional profile, then extrusion is definitely for you.

Short run custom aluminum extrusions

Consulting on Specifications Tolerancing

On Demand Rapid Prototyping Full-scale Production

ISO9001: 2015 Competitive Prices

Why Choose Winners Rapid With Aluminum Extrusion ?

CUSTOMIZATION EXPERTS

Winners Rapid can create an extensive range of custom shapes, sections, extrusions, lengths, and machining.Different aluminum extrusion alloys have different properties and benefits, so it’s important to explore different types of alloys to discover what works best for a project.

FAST TURNAROUND

Need it fast? Trust Winners Rapid to manage your project and deliver your parts on-time, to specification and at a competitive price to get you what you need for your project.

EXTENSIVE RANGE OF VALUED-ADDED SERVICES

In addition to our aluminum extrusion capabilities, we offer in-house preparation and processing services such as surface preparation and finishing, CNC machining, cutting, deburring, drilling, punching, and tapping.

Typical Aluminum Extruded Shapes

Aluminum extrusions take on many different forms. For customers with highly specific or unique requirements, we fulfill custom design requests.Some of the most common shapes include:

Solid shapes: such as solid bars and rods with various cross-sections (e.g., circles, rectangles, squares, and more)

Semi-solid shapes, such as angles, channels, and other partially open forms

Hollow shapes, such as tubes with various cross-sections (e.g., circles, rectangles, squares, and more)

Once the fabrication process is completed, you have the option of finishing your rapid extruded parts. Extrusions offer a production surface finish, and are typically not post processed, but we don’t want to limit your options. Finishes include Powder Coating, Painting, Silk Screening, Pad Printing, E-Coating and Anodizing.

Get QuoteThe Type of Material For Aluminum Extrusion

Due to aluminum is naturally coated with a surface oxide layer, it doesn’t corrode, and extrusion further enhances this property.Besides,aluminum is extremely light-weight, yet its density doesn't compromise its strength—it can also tolerate high temperatures without producing toxic fumes, and is a good conductor of heat and electricity.

At Winners Rapid, our team accommodates project requests with the following grades of aluminium are available for extrusion. Do you require a specific temper such as T5 and T6? Contact us today and we’ll help you find the perfect material.

Aerospace , Electronics , Appliances , Military , Automotive

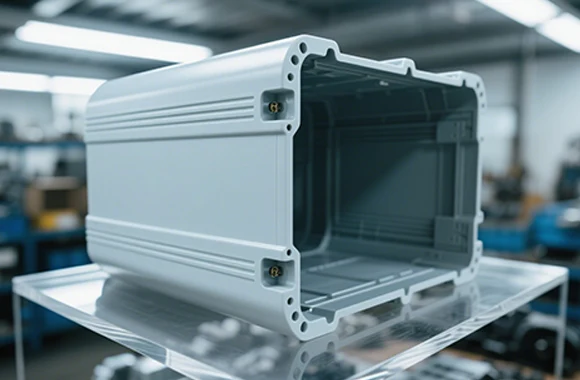

Fitness Equipment , Modular Office Partitions , Enclosures

Retail Displays , Furniture , Medical Equipment , Sporting Goods

Construction , Food Processing , Lighting Fixtures , Office Equipment

Various Range Of Application

Today, aluminum extrusion is used for a wide range of purposes, including components of the International Space Station. These diverse applications are possible due to the advantageous attributes of aluminum, from its particular blend of strength and ductility to its conductivity, its non-magnetic properties and its ability to be recycled repeatedly without loss of integrity. All of these capabilities make aluminum extrusion a viable and adaptable solution for an growing number of manufacturing needs.All of these capabilities make aluminum extrusion a viable and adaptable solution for an growing number of manufacturing needs.

Aerospace , Electronics , Appliances , Military , Automotive

Fitness Equipment , Modular Office Partitions , Enclosures

Retail Displays , Furniture , Medical Equipment , Sporting Goods

Construction , Food Processing , Lighting Fixtures , Office Equipment

Advantages of Extrusion Molding Parts

Low cost per manufactured part , Great flexibility of operation

Continuous operation , Good mixing (compounding)

High strength-to-weight ratio , Variety of size and shapes

Variety of size and shapes , Surface finish obtained is good

Resistance to corrosion , Electrical and thermal conductivity

Good mechanical properties obtained in cold extrusion

General Lead Times

Extrusion Samples

3 to 5 weeks after receipt of order

Production Samples

3 to 5 weeks after sample approval

Fabricated Extrusion Samples

5 to 8 weeks after receipt of order

Fabricated Production

5 to 8 weeks after sample approval

Secondary Finished Part Samples

8 to 10 weeks after receipt of order

Secondary Finished Production Parts

8 to 10 weeks after sample approval

Assembly Samples

10 to 12 weeks after receipt of order

Production Assemblies

10 to 12 weeks after sample approval

Quality Assured Aluminum Extrusion Parts

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts. Material Certification, Full Dimensional Report , Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges.With high-precision industrial manufacturing, a variety of available finishes and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.

The Benifits Of Work With Us

With a vast range of manufacturing processes and finishing options under one roof, Winners Rapid has the flexibility, capability and expertise to deliver your aluminium extrusion project.Winners Rapid experienced in the aluminium extrusions for our customers many years, delivering high precision, complex profiles to clients from a vast range of industries. Normal tolerances to EN755-9 are possible and a number of finishes including anodizing are available.

Complete solution. Not just raw aluminum extrusion profile.

Take on small orders,no Minimum Order Quantity.

Fast development time for aluminum extrusion mold

Low cost through our economy of scale, and never compromise in quality.

Familiar with needs in the following applications: glass building, solar panel, instrument enclosure, LED heat sink, and high precision printer parts.

Our ISO 9001 accreditation ensures quality throughout the process. Trust Winners Rapid to deliver you parts on time and to specification.

Choose a Aluminum Extrusion Partner You Can Trust to Handle it All

Winners Rapid offers provide total solution of aluminum extrusion products which from aluminum extrusion, to surface finish, to machining, cutting and assembly to meet your most complex design requirements.To learn more about our aluminum extrusion capabilities or partner with us on your next project, contact us or request a quote today. We will get back to you to answer and address any questions or concerns you may have about the process or your specific needs.

Non-disclosure agreements

Winners Rapid are under strict NDA agreement,we are happy to sign company specific NDAs.

Except for our sales and senior management know you ,we use anonymized 2D drawings & files to share with our production engineers who produces your parts.