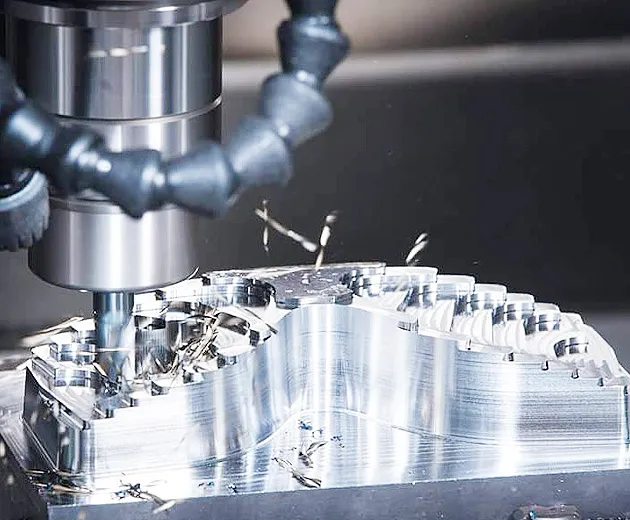

CNC Machining Prototype & Production Services

Fast Turnaround / Global Delivery / ISO 9001:2015 Multiple Materials Options,No Minimums,Produce End-Products

Get QuoteCNC Machining Services

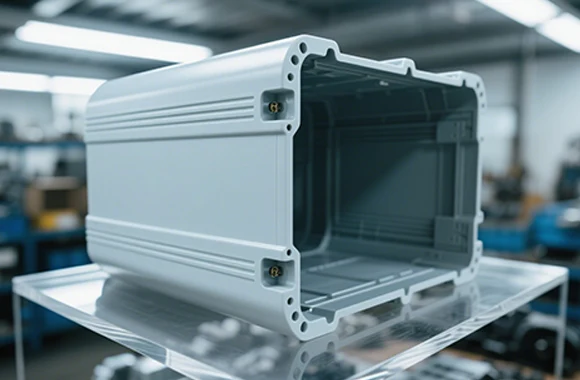

Winners Rapid offers the latest CNC services for both, pre-series and large series production. Our CNC controlled equipment features 3, 4, 5 axis CNC machines with three and four jaw chuck work holding, EDM, live tooling, pallets, and in-house fixturing and tooling. Our machine shop produces high complexity parts that might seem impossible to the average job shop. The technology and equipment we use enable our machining staff to focus on smart planning, improving workflows and discovering innovations. We are always improving our capabilities to making close tolerance, unique parts an everyday occurrence. You can count on Winners Rapid to deliver the most critical and complex CNC machining products on time and with the highest quality.

To learn more about our CNC production machining services, contact us today. If you’re looking for a partner for your next machining project,

request a free quote from our experts now.

1000+ CNC Machining Projects Delivered To Global Leading Companies

In specific sector of low volume manufacturing, CNC machining plays a vital role in custom manufacturing for machined parts of plastic and metal. Manufacturing in low volumes in CNC machining is also one good assessment solution for the coming mass production schedule.

50+ Metals And Plastics, 10+ Surfaces Finishes

Tolerances From +/-0.005" (+/-0.125mm) to +/-0.001" (+/-0.02mm)

On Demand Rapid Prototyping Full-scale Production

ISO9001: 2015 Competitive Prices

One-Stop Shop For CNC Machining

Winners Rapid services include CNC Milling, Turning and 3D Surface Machining, Drilling, Reaming, Tapping, Thread Milling and more. We also partner with a number of different finishing services to ensure your product looks great.

Quality control equipment, including a CMM, projector,height gauges, surface & hardness testers, and other gauges.Compliance to exact customer specifications.

3, 4 & 5 axis CNC milling and turning machines to meet your custom precision machining requirements.

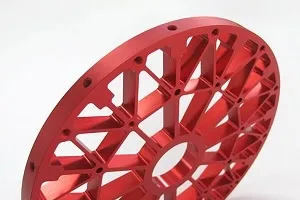

Value-added services such as high polishing, anodizing, chem film, heat treatment, welding, painting, assembling are also available.

In-depth experience working with materials of all types.

5-Axis Machining

Five-axis machining is able to machine complex shapes in a single set-up. This gives greater machining productivity and reduces the time and cost of preparing fixtures. By offering 5-axis horizontal machining capabilities to consecutively machine and drill challenging parts on multiple different planes.

Maximum part size for 5-axis CNC milling

Size

Metric units

Imperial units

Max. part size for metal and plastic materials

650 x 650 x 300 mm

25.5 x 25.5 x 11.8 in

Min. feature size

Ø 0.50 mm

Ø 0.019 in

Advantages Of CNC Machining

CNC machining is highly automated, enabling production both during and outside work hours with minimal input from human workers. When used by skilled engineers, CNC machining can be a major benefit to your company projects which can make the same cut repeatability, you get perfection and precision with each part — ultimately shortening production lead times and saving on costs.

Machined Metal and Plastic Prototypes & Production Parts.

We Guarantee Precision, Reliability, and On-time Delivery.

Our Ability To Complete Orders 100% Correctly Is How We Define Dependability.

Unlimited Project Complexity , Higher Precision And Repeatability

Available For High Volume Manufacturing , High Speed Workpiece Altering

Faster Turnaround , Lower Costs And Greater Efficiencies

Less Human Sourced Fault , Increases In Product Quality And Customer Retention

Improvements In Throughput And Profitability, Enhancements In Capabilities

Multi-Access Productivity And Precision For Complex Large Part Machining

Typical localized part tolerances in .0002″ – 0.005″ Typical overall part tolerances in 0.005″ – 0.020″ Our machines can manufacture parts and components up to 78.7 x 59.0 x 7.8 inches in size.

• Horizontal machining centers

• Horizontal turning centers

• Vertical machining centers

• Vertical twin-spindle turning centers

• A multi-task lathe/mill (dual turning and milling spindle)

Part Application:

Machine Bases And Columns

Machine Bases And Columns

Fixture Plates, Machine Tables

Heavy Equipment Components

Automation And Conveyor Frames

Quality Assured CNC Machined Parts

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts. Material Certification, Full Dimensional Report, Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges.

With high-precision industrial manufacturing, a variety of available finishes on solid metal or plastic parts, and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.

CNC Machining Materials Options

A major advantage in using CNC machining as a prototyping or production technique is the huge range of materials that are available.Winners Rapid are experienced in machining a wide variety of materials including both metals and plastics,while the choice of material depends on the part design and intended application.Please see the list for a sample of the materials we work with. If you desire a material not in this list,please contact Winners Rapid directly if there is a specific material that you require.

Aluminium

AL6061-T6/T651/T6511, AL6063, AL6082, AL7075,T651, AL5083, AL2024,AL5052-H32,

Stainless Steel

SS303, SS304/304L , SS306, SS316, 410, 416,420F,430F,440C,630, 17-4 PH, PH 13-8 Mo

Titanium

Titanium Ti-6Al-4V (TC4), Titanium TA2 ,,GR5 ect

Steel Alloy

#45 Steel, 1018 Steel, 4043 Steel, 4130 Steel, 4140 Steel, 8620 Steel

Other Material

Brass 360, Lithium Bronze,Beryllium Bronze,Copper C101,Magnesium AZ31,A2 Tool Steel, D2 Tool Steel, Inconel 625, 718,Tungsten, Zinc

Plastic Material

ABS,PC+ABS,PC,POM,PP,PEEK,HDPE,PETF,PMMA,PVC,NYLON/NYLON+30%GF,PPS,PEI,PBT,PTFE,UHMW ect.

Standard Tolerances For CNC Machining

CNC machining is ideal for projects requiring production-grade materials and rapid prototyping of tight tolerance plastic and metal parts with excellent surface finishes. Tolerances are greatly affected by part geometry and type of material.

We specify a standard dimensional tolerance of ± 0.005" for CNC machined parts. However, we have much capability to achieve a tighter tolerances on our routers, lathes, 3-axis mills and 5-axis mills. If you require a tighter tolerance, please contact us, as tighter tolerances may increase the cost of your project and have to be clearly defined upon on the 2D drawings of ordering.

ISO 2768 is a standard for general tolerances, specifically covering linear dimensions, angular dimensions and geometrical tolerances.The ISO 2768 standard comes in two parts, namely ISO 2768-1 and ISO 2768-2.

What Surface Finishes Are Available For CNC Machining?

As machined (Ra 3.2μm / Ra 126μin)

Smooth machining (Ra 1.6μm / Ra 63μin)

Polishing (Ra 0.8μm / Ra 32μin or better)

Bead Blasting

Tumbled

Bead blasted + Anodizing type II

What Surface Finishes Are Available For CNC Machining?

✔ As Machined (Ra 3.2μm, 126μin), Smooth Machining (Ra1.6µm, 63 µin)

✔ Brushed (1.2 Ra μm/47 Ra μin), Engraving, Silk Screening, Painting

✔ Bead Blasted, Powder Coating Polishing (0.8 Ra μm/32 Ra μin)

✔ Black Oxide Heat Treating Chromate Conversion Coating (Alodine)

✔ Bead Blasted + Anodized Type II (Matte), Anodized Type III (Hardcoat)

✔ Brushed + Anodized Type II (Glossy) , Brushed + Electropolished (Ra0.8µm, 32µin)

What Surface Finishes Are Available For CNC Machining?

Surface Finishing can provide your parts with a decorative look and alter important chemical and physical properties. That’s why surface finishing has a wide range of applications in different industries and their products.Wide range application of surface finishing can be seen in the following:

As Machined (Ra 3.2μm, 126μin), Smooth Machining (Ra1.6µm, 63 µin)

Brushed (1.2 Ra μm/47 Ra μin), Engraving, Silk Screening, Painting

Bead Blasted, Powder Coating Polishing (0.8 Ra μm/32 Ra μin)

Black Oxide Heat Treating Chromate Conversion Coating (Alodine)

Bead Blasted + Anodized Type II (Matte), Anodized Type III (Hardcoat)

Brushed + Anodized Type II (Glossy) , Brushed + Electropolished (Ra0.8µm, 32µin)