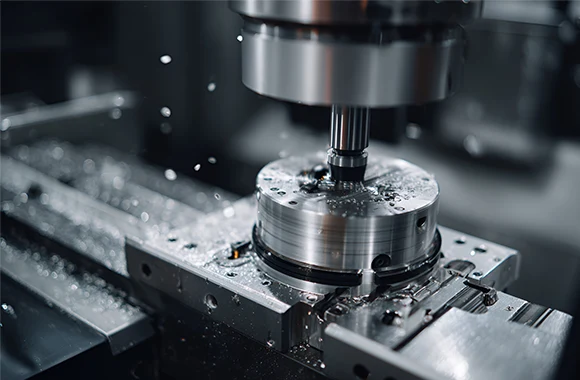

On Demand Plastic Rapid Injection Molding Services

Free DFM / Global Delivery / ISO 9001:2015 Multiple Materials Options , Fast Turnaround , Excellent Surface Finish

Get QuoteInjection Molding Service

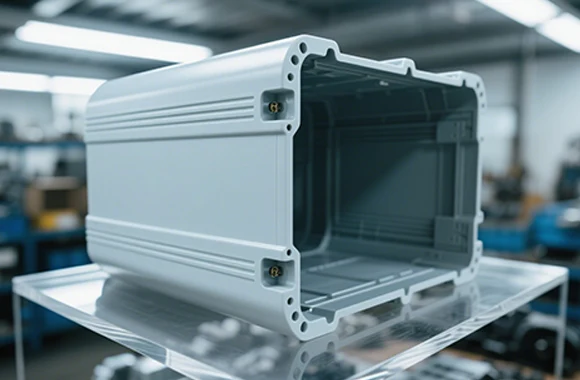

Winners Rapid can help your rapid injection moulding parts as fast as 10-14 days if you need quickly test out the market with low-volume injection molding parts.This ensures a smooth transition from real prototypes to production quality plastic parts. We has expertise working with a range of advanced injection moulding processes including multi-shot moulding, over-moulding and complex mould design.

From concept, to prototype, to completed product, Winners Rapid offer a range of injection molding tools and injection mold designs that can be customized to your manufacturing needs.Winners Rapid offers a single-source global solution that supports any size company’s high-quality, on-demand injection molding for prototypes and production parts.

If you’re looking for a partner for your next plastic injection moulding project, request a free quote from our experts now.

10,000+ Injection Molding Parts Delivered To Global Leading Companies

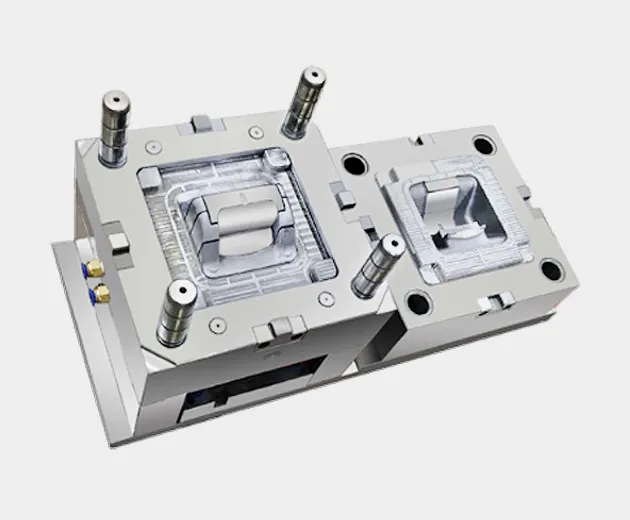

Injection Molding is a manufacturing process for producing parts in large volume. It is most typically used in mass-production processes where the same part is being created thousands or even millions of times in succession.

Wide range of material,produce brand consistency and part reliability in high volume production

Injection Molding produces low scrap rates

The principal advantage of injection molding is the ability to scale production en masse

The price per unit during injection molded manufacturing is extremely low

Rapid Injection Molding For Low & High Volume Manufacturing

Winners Rapid provides high quality plastic injection moulding for low-high volume production.We help rapid tooling and low-volume injection molding of 50-5000+parts for prototyping or small batch production; Bridge tooling and medium volume injection molding of 5,000-50,0000+parts;Production tooling and high-volume injection molding up to 30,0000+ parts.

Up to 25K Parts// 20days

10K Parts / / 10 days

Production Tool / / As soon as 3 weeks

Up to 25K Parts// 20days

Advantages Of Low-Volume Plastic Injection Molding

This is a specialized service offering full production-quality parts but in volumes usually limited to 10,000 pieces or fewer, depending on the process used. Our low-volume molding, also called short runs, are monitored and controlled so you can be assured of all aspects of mold design and build. This type of production is ideal for small and medium-sized businesses or small-batch manufacturing.

Provides a bridge between initial prototypes and high-volume production

Provide rapid access to emerging markets

Allow for faster design changes and more design flexibility

Shorten production lead times

Provides a bridge between initial prototypes and high-volume production

Cost-Effective Rapid Injection Molding

Rapid injection molding provides a better choice for those clients needing low volume molded parts. It can not only manufacture hundreds of production-grade plastic parts for verification test close to the final product, but also provide on-demand production of end-use parts for low-volume manufacturing.

At Winners Rapid, we specialize in rapid molds of both aluminum and steel and low-volume plastic molding, and rush parts to you on a schedule that supports your entire testing and pre-production schedule. We blend traditional injection mold tooling methods with rapid mold tooling to provide cost-effective and rationalized advice from designs, materials, production processes, manufacturability, etc.

At the same time, when the design is stable or volumes are growing, Winners Rapid will move to conventional mold production for your benefit. Diversified solutions for custom plastic means you work with a single source for everything from prototype to production for delivery.

Wide Range Of Finishing , Strict Quality Control , One-Stop Solution

Advantages Of High-Volume Plastic Injection Molding

Injection molding is one of the oldest high-volume manufacturing processes. This is a specialized service offering full production-quality parts in volumes of up to millions of pieces a month. High-volume plastic injection molding allows for high-tolerance precision, low scrap loss, and cost savings.This type of manufacturing is ideal for medium and large-sized businesses or mass production.

Produces more parts at a faster pace

Reduce unit costs and cycle time for the manufacturer

Accurate and consistent, high-quality mass production of parts

Production can often be automated with solid, reliable machinery, even during non-work hours

Minimal post-production work

Over molding;

Insert Molding;

Post pad printing or silkscreen printing.

Rapid prototype making;

Rapid tooling & Low-volume production;

Bridge tooling for functional testing or market testing.

Production tool & High-volume injection molding.

Have to invest injection molding tools;

The part designs have to be careful, other will easily cause molding issues.

The tool building lead time would be long, especially for production tools.

What Materials Are Available For Injection Moulding?

We have experience molding ABS, PC/ABS, PC, PEEK, ULTEM, and Glass-filled Nylon. Additionally, we can apply textures and match your color specifications.

Molding Materials

ABS

ABS(FR)

ABS+30%GF

ABS+PC

ABS+PC(FR)

ASA

HIPS

PC

PC+10%GF

PMMA(Acrylic)

PP

PP+10%GF

PP+20% Talc

POM(Acetal,Derlin)

Nylon6

Nylon66

Nylon66+20%GF

Nylon66+30%GF

TPE(With differnece hardness)

HDPE

LDPE

PPSU

PVC

TPU(With differnece hardness)

PBT

Available Surface Finishes For Injection Molding

Many surface features must abide by the industry standards of the Society of the Plastics Industry, or SPI. These standards in the plastics industry identifies the cosmetic quality of plastics. The SPI standards specify 12 grades of mold finish in four different categories that range from smooth mirror-like finish to a rough dull surface.

Smooth And Glossy Finish

Semi-Glossy Finish

Matte Finish

Textured Finish

For the smoothest and glossiest finishes, SPI grades A1, A2, and A3 are suggested. These grades involve the use of hardened tool steel molds with a buffed mold surface using fine diamond powder. The mirror luster gives a smooth and shiny finish that is almost mirror-like. Products like visors, plastic mirrors, and optical goods are made using these sorts of finishes.

Finish

SPI Grade

Typical Surface Roughness Ra (μm)

Super High Glossy finish

A-1

0.012 to 0.025

High Glossy finish

A-2

0.025 to 0.05

Normal Glossy finish

A-3

0.05 to 0.10

One step below the SPI grades above are grades B1, B2, and B3 which deliver a semi-glossy finish using a hardened tool steel mold with some sheen on its surface. The mold surface is polished with emery cloth or ultra-fine grit sandpaper. The semi-glossy finish is a great way to hide machining, molding, and tooling marks.

Finish

SPI Grade

Typical Surface Roughness Ra (μm)

Fine Semi-glossy finish

B-1

0.05 to 0.10

Medium Semi-glossy finish

B-2

0.10 to 0.15

Normal Semi-glossy finish

B-3

0.28 to 0.32

Perhaps one of the most popular surface finishes is the matte finish. SPI classifies this finish type across grades C1, C2, and C3. The molds used for matte finish are polished using fine stone powders. Diecast parts, industrial parts, and consumer goods all use a matte finish. This finish not only gives a good aesthetic appearance, but also helps mask machining marks.

Finish

SPI Grade

Typical Surface Roughness Ra (μm)

Fine Matte finish

C-1

0.35 to 0.40

Medium Matte finish

C-2

0.45 to 0.55

Normal Matte finish

C-3

0.63 to 0.70

Lastly, we have the textured finish, classified as SPI grades D1, D2, and D3. The mold used for the textured finish is first smoothened using fine stone powder and then dry blasted with aluminum oxide and sometimes glass bead. A textured finish gives a good grip quality on the surface, hides deformations and marks, and at times even helps mask fingerprint smudges.

Finish

SPI Grade

Typical Surface Roughness Ra (μm)

Satin Textured finish

D-1

0.80 to 1.00

Dull Textured finish

D-2

1.00 to 2.80

Rough Textured finish

D-3

3.20 to 18.0

How to work Winners Rapid For Rapid Injection Moulding?

Once we receive your request for quote and engineering data, our process for injection molding is as follows:

1.We provide a quote typically within 48 hours

2.We receive your purchase order and we prepare a Design for Manufacturability (DFM) report for your approval. In that report will make suggestions (if any) to improve the part. We will also detail our strategy for the design of your mold including, gating, ejector pin placement, mold flow analysis, and project milestones. The report is typically ready 1 week after purchase order receipt

3.Once you approve your DFM report. We begin building your mold and depending on part complexity take will take 3 to 8 weeks

4.When your mold is complete we will send you the first test parts (T1 parts) for your feedback. In your quote and project plan, we will allow for 3 iterations (T1, T2 and T3) so we can incorporate your feedback and fine adjustments. We will not apply a texture to the mold until you approve the part geometry

5. We produce the quantity of parts you ordered and ship them to you with inspection reports and material certifications

Choose a Rapid Injection Moulding Partner You Can Trust to Handle it All

Whether you’re looking for a few fast prototypes, thousands of market-ready consumer plastics, or a million production parts, Winners Rapid can provide what you need. Our capabilities range from cast urethane for up to 25 parts, to aluminum tools for a couple thousand parts, to hardened steel tools for plastic injection molding at high volume. To provide an accurate quote we ask that you provide a 3-D CAD model and a 2-D drawing that details tolerances, material, color, texture, inserts and any other details that would not be included in the 3-D model.

Non-disclosure agreements

Winners Rapid are under strict NDA agreement,we are happy to sign company specific NDAs.

Except for our sales and senior management know you ,we use anonymized 2D drawings & files to share with our production engineers who produces your parts.