Effective and Efficient Low-Volume manufacturing

50 to 100,000+ Parts / Global Delivery / ISO 9001:2015

Get QuoteOn Demand Low Volume Manufacturing

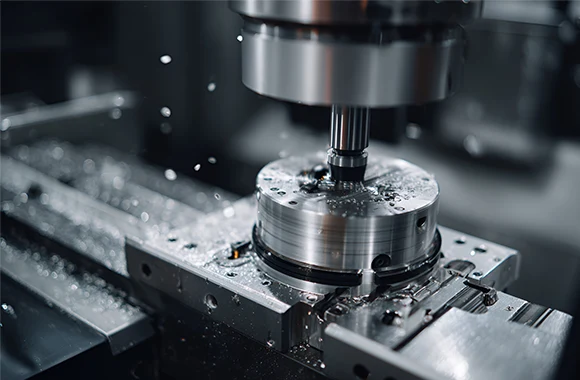

You need metal and plastic parts,but you do not need millions...at least not right away. So how do you justify spending tens of thousands of dollars on tooling that will only be used to manufacture a limited quantity of parts? You're in luck! The Winners Rapid has a solution for you. Low-Volume Manufacturing is an ideal solution for managing your inventory and testing the market before producing larger quantities.To keep up with demand, production lines turn to low-volume manufacturing. Through our low-volume manufacturing service, we can provide you with hundreds of thousands of parts so that you can get products to market in weeks instead of months.

Many of our clients need more than just machined parts, which is why we also offer 3D printing and plastic injection molding and other services that meet equally stringent quality standards and compressed turnaround times, making a full suite of rapid manufacturing technologies that provide advantages for prototyping and production available to our customers. To experience the rapid response and radical quality that drives our CNC machining and low-volume manufacturing solutions, upload a 3-D model file and request A Free Quote today.Learn more about our low-volume production capabilities:

Why Choose Winners Rapid for Low-Volume Manufacturing?

Produce customized products and bring a product to market quickly with low-volume production and bridge manufacturing. Low-volume production could turn to high-volume production and more revenue if the manufacturer gets products out quickly and efficiently.Let us know about the details of your production, and we will recommend you the best suitable production method based on the object’s attributes.

On-demand Manufacturing

There is no minimum quantity requirement,we provide customer-oriented manufacturing solutions for different type of projects.

Fast Turnaround

Quotes within hours,parts within days,our quick turnaround times ensure that you’ll get your prototypes to help you accelerate speed products to market.

Competitive Pricing

We have built up an efficient rapid manufacturing system which allows us to offer competitive prices that can match any offer.

High Precision Tolerances

The tightest tolerance +/-0.001" to +/-0.0002" (+/-0.025mm to +/-0.005mm), we are able to make precise parts with tight tolerances for aerospace and medical industries.

Wide Range of Materials

We supply a wide array of commercial-grade plastics ,metals and elastomers materials suitable for Rapid Prototypes and On-demands Part Manufacturing.

Experience & Professional

We have a team of professional engineers, machinists and skilled craftsman with more than 10 years of experience, which allows us to completely grasp your exact project requirements from prototype to production.

Free Manufacturing Analysis

We provide free,professional and quick-turn manufacturing feasibility analysis for Rapid Prototypes and On-demand Production Parts.

Choose Low-volume Manufacturing When You Need…

Short lead times . Cost-efficient models. High accuracy to closely match reality .High-quality finishing options

Get Your Rapid Prototyping QuoteWhat is Low Volume Manufacturing?

Customized orders in shorter times can introduce the product to the market faster, which makes some production lines turn to low-volume manufacturing. Low volume manufacturing generally refers to the production of 50 to 100,000 parts, acts as a bridge between rapid prototype and full-scale production in millions quantity. Our Quick-turn CNC machining services and other technologies provides low volume production with premium quality and short cycle time to help you get the products to market quickly.

What is Low Volume Manufacturing?

Functional prototypes, Production-grade engineering prototypes

Low-volume sheet metal fabrication

High Quality customized products

Plastic injection molded parts for pilot runs

Functional prototypes, Production-grade engineering prototypes

Rapid bridge tooling or bridge production

Pre-production components for verification tests

Question and Answer

How to Process Low Volume Manufacturing?

Our experienced engineers are familiar with all processes,we determine your best pathway to the marketplace based on your project’s goals and expectations, providing cost-effective and rationalized advice from designs, materials, production processes, manufacturability, etc.Depending on the processing methods, manufacturing processes, mold tooling and materials being used, our Rapid Prototyping and Low-volume manufacturing generally involves the production range of 1 to 100K parts. Winners Rapid is capable of many different technologies that are capable of small-batch production with customization. Whether you select CNC machining, Vacuum Casting, 3D printing and Sheet Metal manufacturing technology, you will be impressed by our quick, efficient and high-quality service.

Why Has Low Volume Manufacturing Become Popular?

Short-run and low-volume production can be achieved by different manufacturing methods,it makes sure that you will move from prototype to production smoothly. Low volume production has seen a steady surge of popularity in recent years. Many industries have discovered that low volume production allows them to spend less time and money on materials and tooling while getting to market faster.Low volume manufacturing has also allowed brands to respond to design changes quickly.

What to Consider for Low Volume Manufacturing?

Even though low volume manufacturing is a quick turn production method, there are also many factors that will determine if you should get started with low volume manufacturing. The first one is the quantity, the production run of 50 to 100,000 parts are suited for the way. In addition, the complexity of the parts, materials, tolerances, surface finish, and more aspects should be considered. For example, the complexity will raise the cost of production, and the surface quality requirements will determine the machining process of post-processing techniques.

Quality Guarantee

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts. Material Certification, Full Dimensional Report, Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges.

With high-precision industrial manufacturing, a variety of available finishes on solid metal or plastic parts, and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.

Advantages of Low Volume Manufacturing Applications

Makes iterations and design more flexible

Reduces risk by lowering the initial investment

Save time with no minimum order

Lower Volume can reduce time to market

Creates opportunities to save production costs

Bridge the gap to production,marketing can start before mass production.

Critical Factors using Low Volume Manufacturing

It might reveal many hidden problems before the production starts

Some applications cannot be realized with the original material

It might reveal many hidden problems before the production starts

Low-Volume Manufacturing With Winners Rapid Today

The effective short-run or low-volume production solutions make all stakeholders benefit in the product lifecycle, from design to manufacture and all the way to the supply chain and consumers. Contact our project manager today to start your project with a free quote.

Quick-Turn Manufacturing

Multiple Materials

Guaranteed Quality