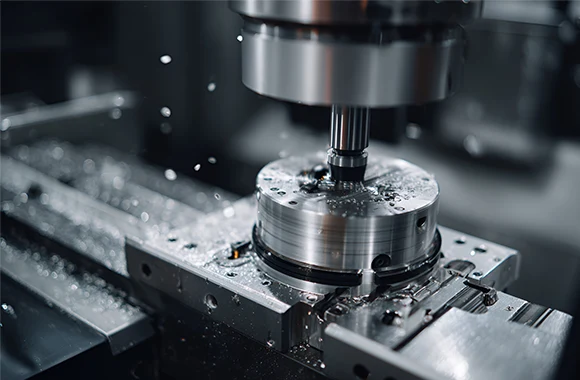

CNC Machining Prototype & Production Services

Fast Turnaround / Global Delivery / ISO 9001:2015Multiple Materials Options,No Minimums,Produce End-Products

Get QuoteRapid Prototyping Services

At Winners Rapid, we understand how important it is for you to get all your new products to market in the fastest and most efficient ways possible. Our rapid prototyping services were designed with all of these objectives in mind — giving you a unique opportunity to reduce your total time to market — all while maintaining the highest-possible product quality. It provides a fast and economic means of validating such designs before tooling release. Choosing the right rapid prototyping technology is critical to the success of a prototype. Each rapid prototyping technique has its own compromise in terms of cost, speed, material compatibility of the feature, fidelity level and development stage.

Winners Rapid are committed to solve the problem of research and development of new product for the customers.With a range of technologies and services, we are the perfect one-stop-shop for all your rapid prototyping needs.Most of our engineers have over 10 years experience,when we receive your enquiry and 3D CAD file, based on our knowledge and experience, we will assist you in selecting the best prototype method to meet your quality expectations and budget needs.

Expert Rapid Prototyping for Smarter Development

"Fast, efficient, collaborative and win-win" is the concept of Winners Rapid services to the industry line,we uses only state-of-the-art equipment and the latest technologies to provide customers with top quality, precision prototypes.Continue reading to learn more about the rapid prototyping process or send your 3D design file to our international team of engineers for a free quote.Here are the main rapid prototyping processes we offering:

Why Choose Winners Rapid for Rapid Prototyping?

The most important benefit of rapid prototyping is it allows you to thoroughly test your product early on. You can create multiple prototypes in one go, detect some design flaws in your designs, and create more refined ones in a short amount of time.You need to partner with a manufacturer you can count on to make your designs come to life on a timetable that works for you.Here are Why you can trust Winners Rapid to deliver:

Fast instant quote within few hours to 12 hours,we will response you as fast as we can

Fast turnaround with prototype model making 3-9 days ,rapid injection molding 2-5 weeks

Fast instant quote within few hours to 12 hours,we will response you as fast as we can

Deliver prototype and low-volume production quantities,typically from 1 to 10,000+ parts

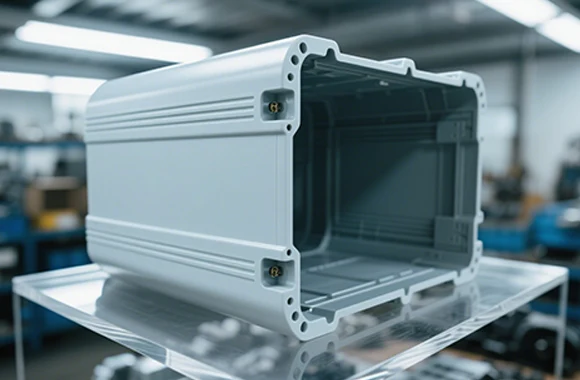

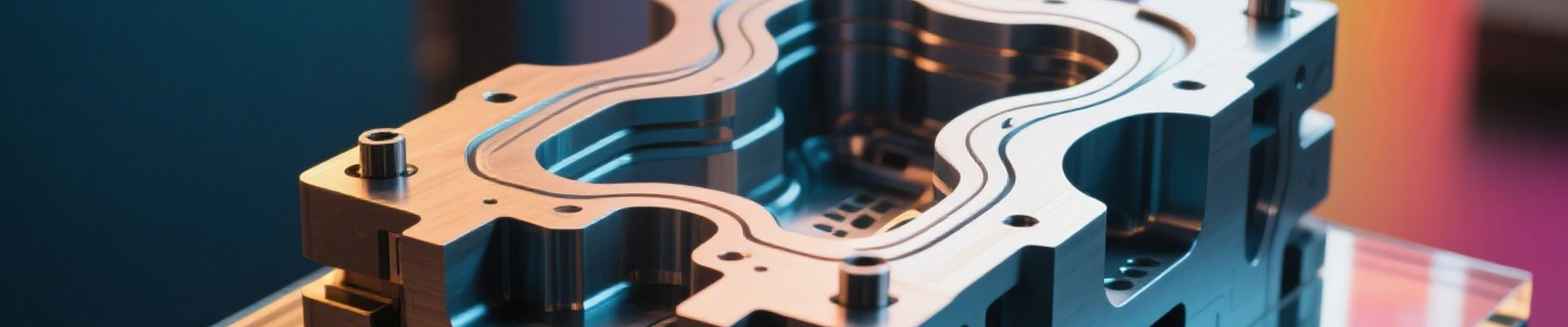

Perform CNC Machining of billet materials. We specialize in CNC machining titanium,stainless steel, steel alloy,aluminum alloy, magnesium, and engineered plastics and many other materials

A team of professional engineers, machinists and skilled craftsman completely grasp your exact project requirements from prototype to production

Provide 3-axis, 4-axis, and 5-axis CNC machining ,plastic injection molding,sheet metal,vacuum casting and other technologies

Machine parts with tightest tolerance +/-0.001" to +/-0.0002" (+/-0.025mm to +/-0.005mm)

Efficient, accurate and cost effective process system to deliver superior parts that requiring certifications, CMM reports

One-stop surface finishing, component installation, component assembly, and more to meet your most difficult manufacturing challenges

Choose Rapid Prototyping When You Need…

Short lead times. Cost-efficient models. High accuracy to closely match reality. High-quality finishing options

Get Your Rapid Prototyping QuoteWhy is rapid prototyping important?

In this fast-moving modern-day consumer market, companies need to develop and introduce new products faster to remain competitive. Since faster product development and technology innovation are key to a company’s success, rapid prototyping becomes the most important element of new product development. The following objectives are achieved through rapid prototyping.

Faster new product development– Test the market with your product before production

Reduced overall product development cost

Elimination or reduction of risk,early stage design/concept validation of form, fit, and function of the design

Final stage product verification against the technical requirement and business objectives

Allows functionality test the objectives of the concept and to finalise the specification

Improved and increased user involvement--prototype gives the end users, clients, customers, user participants hands-on user experience to get feedback

Applications of Rapid Prototyping

3D Printing Prototyping, CNC Prototyping Machining,Sheet Metal Prototyping, Urethane Casting Prototyping

Metal Prototyping,Plastic Prototyping,Rubber Prototyping

Appearance Prototyping,Function Prototyping

Digital Communication Prototyping,Medical Equipment Prototyping,Intelligent Home Prototyping,Robotic Prototyping, Office equipment Prototyping, Financial equipment Prototyping,Aerospace Prototyping, Electric Transportation Equipment Prototyping, Military Equipment Prototyping, Automotive Prototyping

Question and Answer

What should you consider when choosing a prototyping material?

Mechanical properties / Manufacturing characteristics / Appearance / Cost

What mechanical properties are required of the prototyping material?

The main factors determining material choice include mechanical characteristics such as stress, heat resistance and elasticity of the part.Here are the most common factors: Strength.Elasticity.Hardness.Durability.Temperature.Resistance.Transparency.Moisture resistance.Impact resistance. Other factors to consider in material choice include the material’s suitability for manufacturing and how close to the actual material the prototyping material is.Please note, these are general guidelines. In all cases if you do not find a material you are looking for or need guidance, please contact us. We are always happy to help.

Quality Guarantee

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts. Material Certification, Full Dimensional Report, Advanced Inspection Equipment

Our quality assurance pervades every aspect of what we do—from the quoting phase to final delivery.Our expert quality technicians are trained to operate a wide range of process and quality control equipment—including CMM, Projector, Surface & Hardness Testers and a wide range of Precision Micrometers, Gauges.

With high-precision industrial manufacturing, a variety of available finishes on solid metal or plastic parts, and our Quality Assurance capabilities, Winners Rapid guarantees your custom parts will be built to your specifications.

Advantages of Rapid Prototyping

Rapid Prototyping saves time & money

Explore projects quickly on a physical level

Communicate projects effectively with clients & customers

Rapid Prototyping opens the possibility of producing complex parts at once

Prevent mistakes in design and functionality

Critical Factors of Rapid Prototyping

In some cases, costs per unit might be higher than using conventional methods

Some applications cannot be realized with the original material

RP might reveal hidden problems before the serial production

Rapid Prototyping With Winners Rapid Today

Our experienced engineering team is dedicated to helping you find the best, most streamlined manufacturing solution to give your business the tools it needs to succeed.Start Your Project With A Free Quote

Quick-Turn Manufacturing

Multiple Materials

Guaranteed Quality