Surface Finishing Service

Your One-stop Shop For Manufacturing And Surface Finishing. Outstanding Results On All Types Of Surfaces And Geometries

Get QuoteSurface Finishing Service

Surface finishing is a broad range of industrial processes that alter the surface of a manufactured item to achieve a certain property. Finishing processes may be employed to: improve appearance,adhesion or wettability, solderability, corrosion resistance, tarnish resistance, chemical resistance, wear resistance, hardness, modify electrical conductivity, remove burrs and other surface flaws, and control the surface friction. An unfinished surface is often called mill finish.

Depending on the needs of your projects, you might use one process or a selection of processes to achieve the final surface finish to achieve the correct product quality. Winners Rapid has a capabilities to meet your most challenging surface requirements via our high and stable performance suppliers nearby our factory. This means a higher efficiency rate, lower risk of variance, and a higher level of accountability for the end product.

High Polished Parts

Plating

Anodize

E-Coating

Sand Blasting

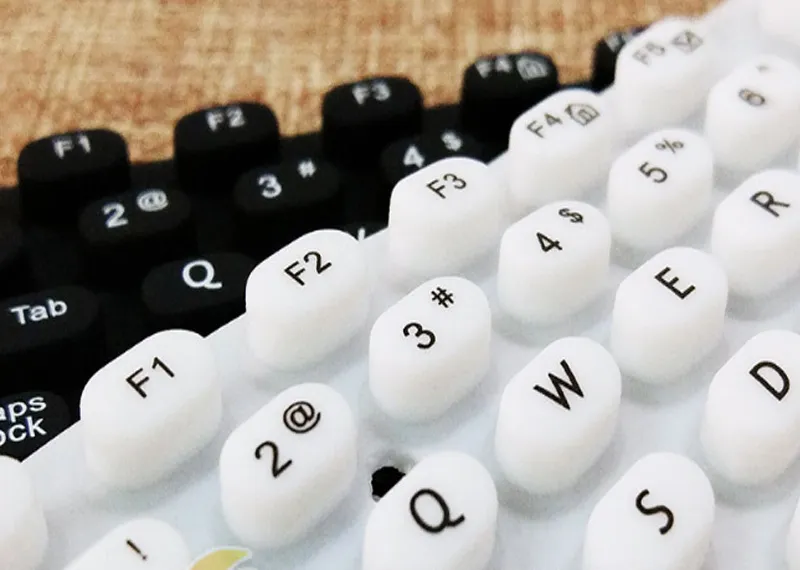

Silk Screen Printing

10 Common Surface Finishing Processes

There are far too many surface finishing processes to list all of them here. But, here are a selection of some common options, many of which you are probably already familiar with,each of metal surface finishing processes plays an important role in the manufacturing process:

Sanding

Probably the most widely-known surface finishing process, sanding involves removing surface material with an abrasive sheet or disk.

Sandblasting

Abrasive beads are propelled onto the surface which removes material rapidly.

Passivation/ Conversion coating

This improves the rust-resistance of steel by removing free iron from the surface with citric or nitric acid

Polishing

Polishing is similar to sanding but using a finer abrasive media,leaving a clean surface with a significant specular reflection.

Heat Treating

It is used to procure desirable characteristics in the material after its finished shape is attained.

Electroplating

A process by which electricity is used to coat one metal (e.g. copper) with a thin bonded layer of another metal (e.g. gold).

Anodizing

Another coating process by which the outer layer of iron oxide on a metal is thickened to improve the mechanical properties.(Type II Anodizing & Type III Anodizing).

Painting

Though not always considered a surface finishing process, painting allows you to improve the appearance and material properties.

Electroless Plating

This treatment method is similar to electroplating; however, it does not utilize electricity. A reduction agent replaces the electricity, and it is contained in the plating solution.

Powder coating

It is a type of coating that is applied as a free-flowing, dry powder,which is typically applied electrostatically and then cured under heat or with ultraviolet light.

Why Choose Winners Rapid For Finishing Services?

Winners Rapid has advanced CNC machining facilities to manufacture quality parts with excellent strength and tolerance.When it comes to your product, performance is vital — but the finishing touches can make all the difference. And we offer various selection of professional finishing services to supplement our manufacturing processes in order to ensure better performance and longevity for your market-ready standout prototype or low-volume product parts.

Wide Range Of Finishing , Strict Quality Control , One-Stop Solution

The Advantages Of Surface Finishing

Numerous types of metal finishing processes are used for a variety of purposes. Some of the general advantages of metal finishing treatments include:

Increased durability , Aesthetic Outlook

Enhanced electrical conductivity , Higher electrical resistance

Higher chemical resistance , Higher tarnish resistance

Corrosion resistance , Reduced Surface Roughness

What Are The Applications Of Surface Finishing?

Surface Finishing can provide your parts with a decorative look and alter important chemical and physical properties. That’s why surface finishing has a wide range of applications in different industries and their products.Wide range application of surface finishing can be seen in the following:

Automotive Parts , Medical Devices , Electronic Enclosures

Aerospace , Marine Industry , Robotics

Telecommunication , Appliances , Hardware

Some Metal Finish Designations

#3 Finish

Also known as grinding, roughing or rough grinding. When the finish is specified as #3, the material is polished to a uniform 60–80 grit.

#4 Architectural finish

Also known as brushed, directional or satin finish.A #4 architectural finish is characterized by fine polishing grit lines that are uniform and directional in appearance

#4 Dairy or sanitary finish

This finish is commonly used for the medical and food industry and almost exclusively used on stainless steel.This finish is much finer than a #4 architectural finish. This finish enhances the physical appearance of the metal as well as increases the sanitary benefits.

#6 Finish

Also known as a mirror finish. This finish is produced by polishing with at least a 320 grit belt or wheel finish.Care will be taken in making sure all surface defects are removed.

#7 Finish

It is produced by polishing with a 280–320 belt or wheel and sisal buffing with a cut and color compound.This is a semi-bright finish that will still have some polishing lines but they will be very dull.

#8 Finish

Also known as a mirror finish. This finish is produced by polishing with at least a 320 grit belt or wheel finish.Care will be taken in making sure all surface defects are removed.

Question and Answer

Which Finishing Process Is Suitable For You?

Different surface finishes can be applied to different materials. Choosing the right surface treatment for your steel, aluminum, copper, and brass parts can be confusing. We encourage our customers to add a note to their drawings indicating whether the dimensions apply before or after plating.

What The Color’s Selection You Would Like To Choose?

We offers a wide selection of colors (gloss & matte) for your finishing process in order to make your parts fit your needs as much as possible. We offer different color qualities, ranging from classic paints to automotive grade paints. In addition to our colour selection, we give you the possibility of choosing more specific and particular colors to realize your vision.

What Kind Of Transparent Effect Do You Want?

Depending on the geometry of your prototype, different levels of transparency are available(Semi-Clear & Ultra-Clear & Smoked-Clear).

What Surface Finishing Are Good For Corrosion Resistance?

Anodizing / Powder Coating / Chromate Conversion Coating / Liquid Painting At Winners Rapid we use all of these finishing methods and more to produce any kind of surface you desired on your rapid prototype or CNC machined parts. Contact us today for a free quote and project review and we will show you how we can put these methods to work on your next project.

START WORKING WITH Winners Rapid YOU CAN TRUST

With many years of experience, we deliver guaranteed high quality parts. We pay meticulous attention to your requests and we don’t compromise on quality or accuracy for our Rapid Prototyping and Low Volume Manufacturing Services.

YOU SEND / WE QUOTE / WE BUILD / WE DELIVER

Get Quote