CNC Milling Prototypes and Production Parts

As Fast As 3 Days / Global Delivery / On-demand Manufacturing

Get QuoteCNC Milling Services

From Prototypes to full production runs,Winners Rapid is a highly responsive, ISO-certified CNC machining supplier. We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes.We make the parts from the drawings fully in our factory via various capabilities include CNC center, CNC turning, milling, grinding, drilling, tapping, EDM , wire cutting and deburring etc.Start your CNC Milling project today and let Winners Rapid manage the entire process for you.

1000+ CNC Milling Projects Delivered To Global Leading Companies

In specific sector of low volume manufacturing, CNC milling plays a vital role in custom manufacturing for machined parts of plastic and metal. Manufacturing in low volumes in CNC milling is also one good assessment solution for the coming mass production schedule.

50+ Metals And Plastics, 10+ Surfaces Finishes

Tolerances From +/-0.005" (+/-0.125mm) to +/-0.001" (+/-0.02mm)

On Demand Rapid Prototyping Full-scale Production

3-Axis Milling 4-Axis Milling 5-Axis Milling

One-Stop Shop For CNC Milling

Winners Rapid support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes. If your project has an urgent schedule, in the meantime require relatively high tolerance, CNC milling can be the most suitable process for you.

In-depth experience working with materials of all types.A variety of CNC machined metal and plastic part options are available for an instant online quote.

5 axis CNC Milling is able to machine complex shapes in a single set-up. This gives greater machining productivity and reduces the time and cost of preparing fixtures.

Value-added services such as high polishing, anodizing, chem film, heat treatment, welding, painting, assembling are also available.

In-depth experience working with materials of all types.A variety of CNC machined metal and plastic part options are available for an instant online quote.

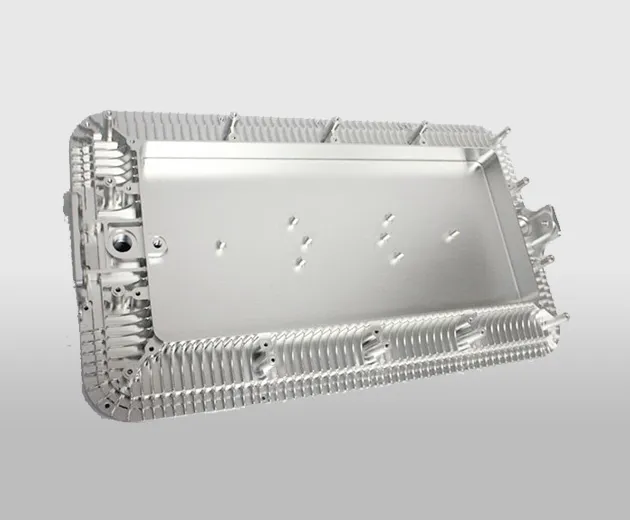

The Capabilities Of CNC Milling

Our 3 aix, 4 axis and 5 axis milling capabilities enable us to create elaborate 3D shapes, intricately detailed features, and high-quality machined surfaces on metal and plastic parts. Along with holes, curves, and slots, we cut angled shapes, channels, and other challenging design elements. With our multi-axis machines, set up is minimized, cycle times are fast, and parts exhibit a high degree of accuracy and repeatability.

Suitable for Large Milling Parts Precision to +/-0.0002 inches on critical features

Different Complex Shapes Serves Multiple High Tech Industries.

High-Speed Turn Around Specializes In Prototypes To Medium & Large Production Runs

Maximum Capabilities For CNC Milling

Part size limitations

Metric units

Imperial units

Aluminum, Copper, Brass, and Plastics

2000x1500x200mm

78.7×59.0x7.8 in

Stainless Steel, Tool Steel, Alloy Steel & Mild Steel

1500x800x400mm

62×30×16 in

Minimum feature size

Ø 0.50 mm

Ø 0.019 in

Quality Assured CNC Milling Parts

ISO 9001:2015 Certified Stands Behind The Delivery And Quality Of Your Parts.

Material Certification Full Dimensional Report Advanced Inspection Equipment

As Machined (Ra 3.2μm, 126μin), Smooth Machining (Ra1.6µm, 63 µin)

Brushed (1.2 Ra μm/47 Ra μin), Engraving, Silk Screening, Painting

Bead Blasted, Powder Coating, Polishing (0.8 Ra μm/32 Ra μin)

Black Oxide, Heat Treating, Chromate Conversion Coating (Alodine)

Bead Blasted + Anodized Type II (Matte), Anodized Type III (Hardcoat)

Brushed + Anodized Type II (Glossy) , Brushed + Electropolished (Ra0.8µm, 32µin)

Application Parts For CNC Milling

✔ Machine, Engine, Turbine, Hydraulic, Shafts,

✔ Turbomachinery Components, Construction Equipment,

✔ Forgings, Jewelry , Valves, Pins, Thread Rod,

✔ Fasteners, Spindles, Sockets, Bushings,

✔ Spacers, Fittings and Standoffs.

CNC Milling Materials Options

A major advantage in using CNC milling as a prototyping or production technique is the huge range of materials that are available.Winners Rapid are experienced in machining a wide variety of materials including both metals and plastics,while the choice of material depends on the part design and intended application.Please see the list for a sample of the materials we work with. If you desire a material not in this list,please contact Winners Rapid directly if there is a specific material that you require.

Aluminium

AL6061-T6/T651/T6511, AL6063, AL6082, AL7075,T651, AL5083, AL2024,AL5052-H32,

Stainless Steel

SS303, SS304/304L , SS306, SS316, 410, 416,420F,430F,440C,630, 17-4 PH, PH 13-8 Mo

Titanium

Titanium Ti-6Al-4V (TC4), Titanium TA2 ,,GR5 ect

Steel Alloy

#45 Steel, 1018 Steel, 4043 Steel, 4130 Steel, 4140 Steel, 8620 Steel

Other Material

Brass 360, Lithium Bronze,Beryllium Bronze,Copper C101,Magnesium AZ31,A2 Tool Steel, D2 Tool Steel, Inconel 625, 718,Tungsten, Zinc

Plastic Material

ABS,PC+ABS,PC,POM,PP,PEEK,HDPE,PETF,PMMA,PVC,NYLON/NYLON+30%GF,PPS,PEI,PBT,PTFE,UHMW ect.

Choose a CNC Milling Partner You Can Trust to Handle it All

If you need custom milling, one-of-a-kind prototypes, other precision CNC milled parts, or complete turnkey service, look no further than Winners Rapid. Our on-demand manufacturing can deliver high-quality metal or plastic milled parts for rapid prototyping or low-to-high volume production runs.Request a quote today—most quotes are returned within fews hours.

Non-disclosure agreements

Winners Rapid are under strict NDA agreement,we are happy to sign company specific NDAs.

Except for our sales and senior management know you ,we use anonymized 2D drawings & files to share with our production engineers who produces your parts.